Tube Cosmetics: Spot Defects

The terms spots and blems are two very common terms that are heard in the night vision world. But what are they and how do they happen and is there a difference between the two?

Spots or Spot Defects are little black spots that can appear in an intensifier tube. They can happen for several reasons, but they all happen during the actual manufacturing process of the image intensifier tube. The manufacturing process for image intensifiers is highly technical and intricate.

Spots can happen for a variety of reasons, but the most common are bright spots burned out by the factory, broken light fibers, and debris. Since these spots appear as black artifacts, they are often confused with blems. Blems do not happen during the manufacturing process. Blems happen from damage to the tube from use. These happen for a variety of reasons, which we have addressed in our light damage article.

Like all manufacturing, consistent perfection is unrealistic, so acceptable standards were created. Because spots happen so frequently in the manufacturing process of intensifier tubes there is a spot spec for each tube. A spot spec is the number and location of allowable spots in a tube. For a spot to count as a spot it must be larger than .003” in diameter. It is important to note that spots smaller than .003” are a possibility and are often described as pepper.

Spot specs on tubes vary, but there are three main categories of spot specs: Commercial, Milspec, and Aviation. These three spot specs all have different allowances across the zones of the tube and is important to understand before making your night vision purchase. It is also very important to understand that intensifier tubes are like diamonds they all are different and no two are exactly alike.

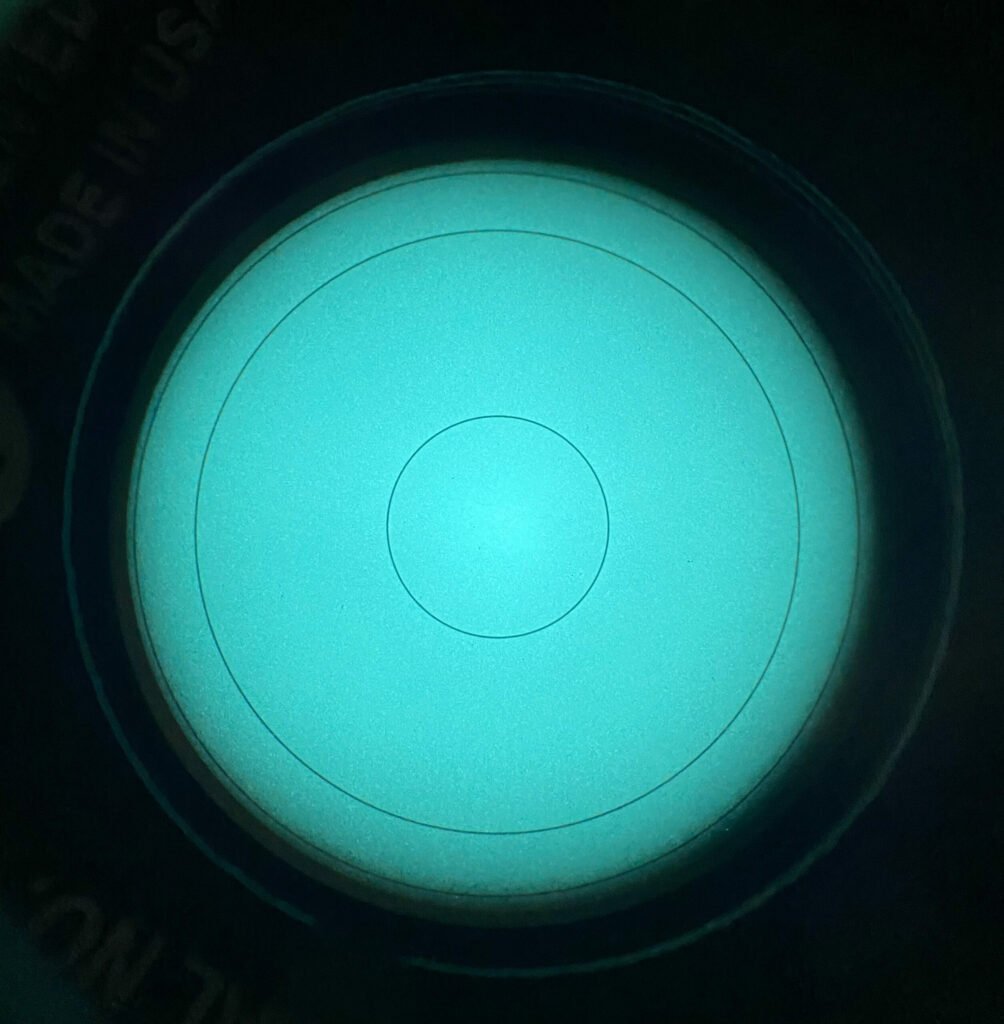

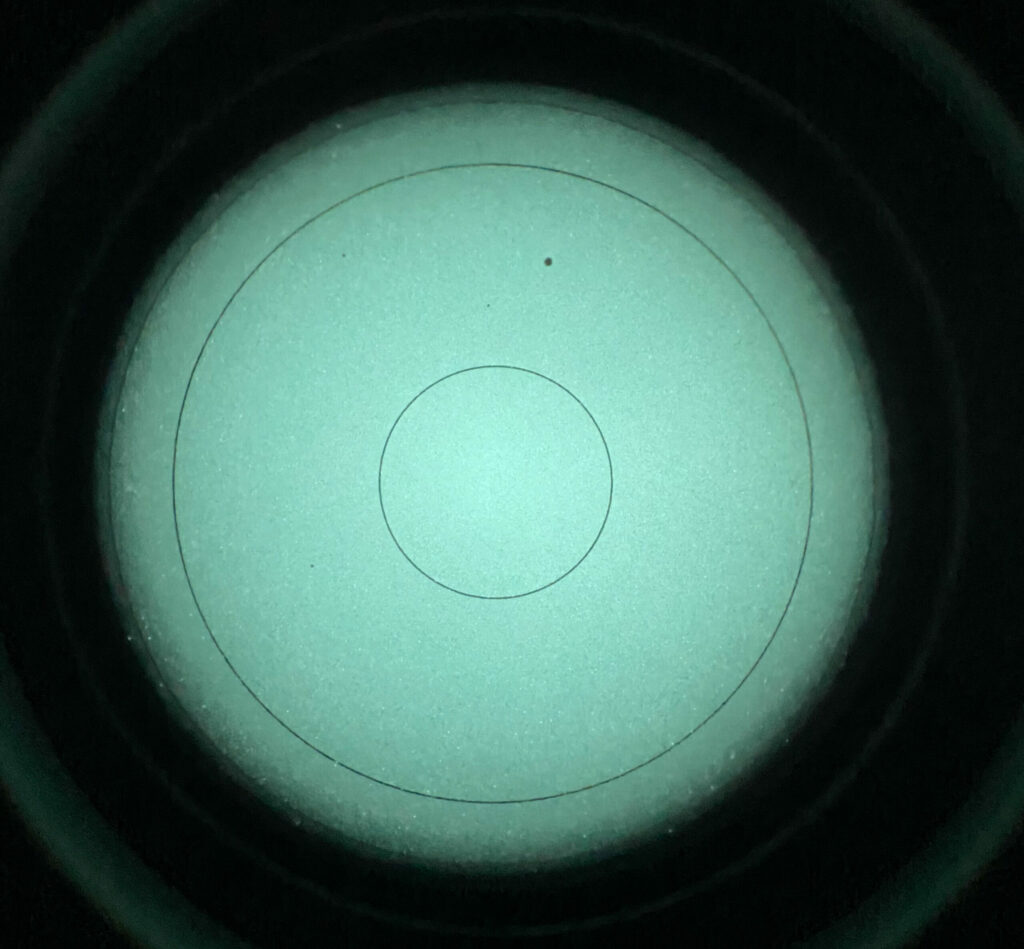

Spots are measured on proper night vision test equipment both at the factory and through our quality control processes. Spots are measured using Hoffman test equipment which include a zone chart for proper testing. Here is an example of what it looks like to view a tube on a Hoffman zone chart. The inside area of the inner most circle is zone 1. The area outside of zone 1 and inside of the second circle is zone 2. The outermost area outside of zone 2 is zone 3.

A commercial spot spec is the broadest spot spec. These are tubes that fail milspec acceptance testing. Commercial spot specs differ from manufacturer but generally speaking if is max 4 spots greater than .003” per tube with an allowable zone 1 spot. The allowance for a zone 1 spot larger than .003” is what typically sets a commercial spot spec apart from a milspec spot spec. The following tube picture is an example of an acceptable tube per a commercial spot spec.

Pictured above is a commercial grade spot spec example. This tube reads 3 spots, one in zone 1, one in zone 2, and one in zone 3.

Pictured above is a commercial grade spot spec example. This tube reads 3 spots, one in zone 1, one in zone 2, and one in zone 3.

A commercial spot spec is the broadest spot spec. These are tubes that fail milspec acceptance testing. Commercial spot specs differ from manufacturer but generally speaking if is max 4 spots greater than .003” per tube with an allowable zone 1 spot. The allowance for a zone 1 spot larger than .003” is what typically sets a commercial spot spec apart from a milspec spot spec. The following tube picture is an example of an acceptable tube per a commercial spot spec.

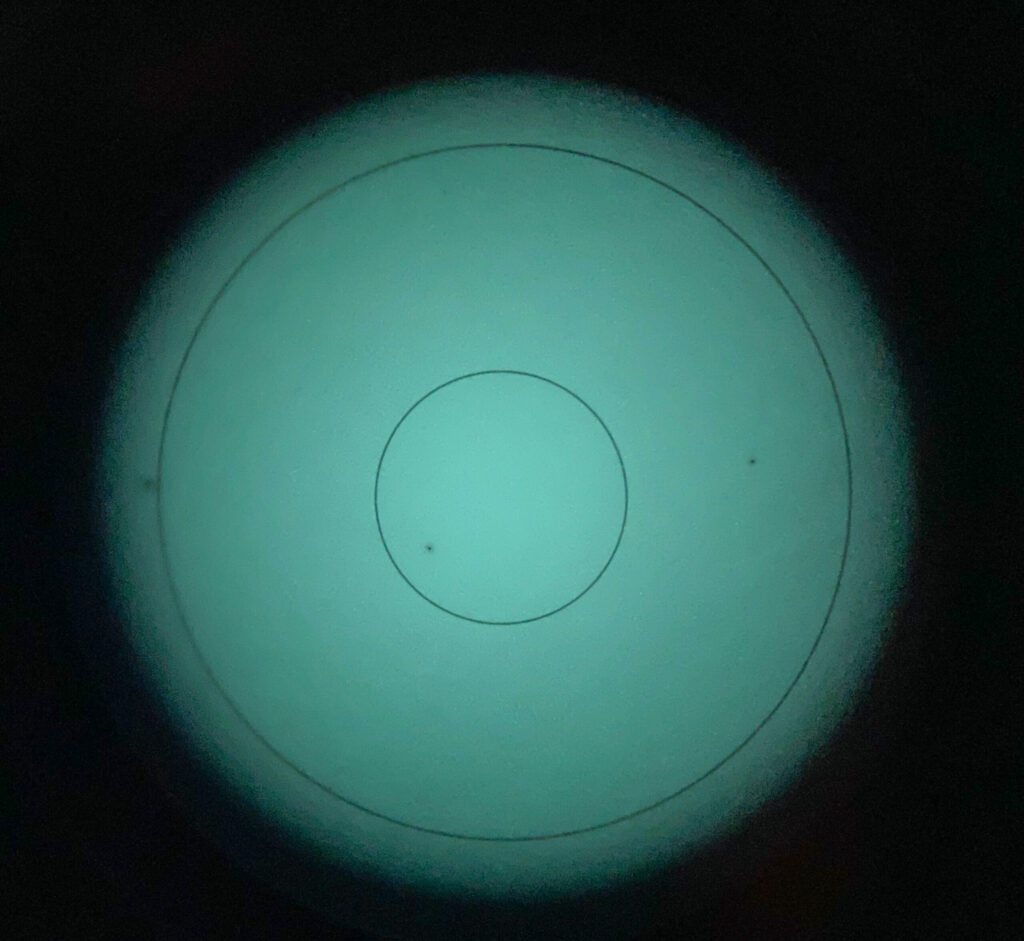

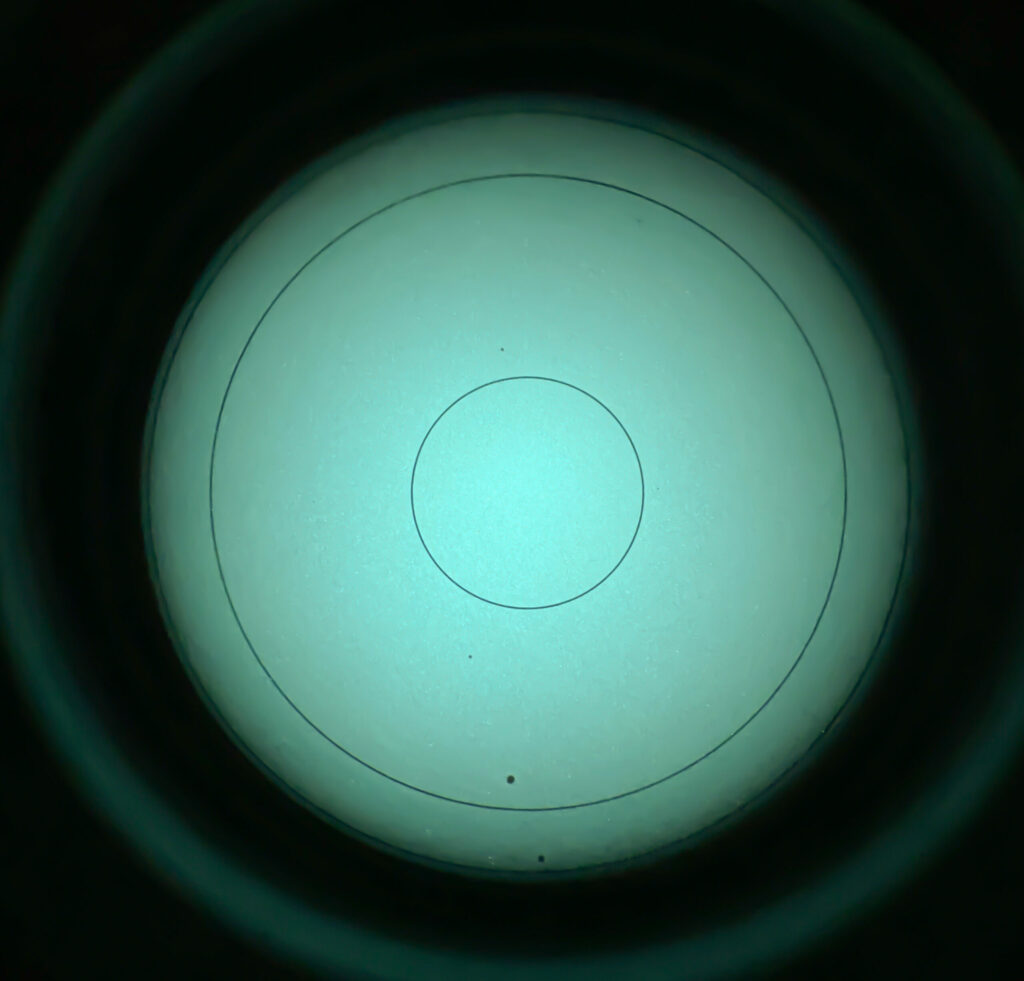

A milspec spot spec is what has been accepted by the military to meet their ground tube needs. A milspec spot spec is what comes standard in both milspec tubes and most L3 helmet mounted finished goods. A milspec spot spec allows for max 4 spots greater than .003” per tube with no spots in zone 1 greater than .003”. Within this max of 4 allowable spots, there can be no more than 3 spots in zone 2 or 3 in one tube. Like every spot spec, spots equal to or smaller than .003” are acceptable in any zone and do not count as spots.

Pictured above is a milspec grade spot spec example. This tube reads one spot in zone 2.

Pictured above is a milspec grade spot spec example. This tube reads two spots, one spots in zone 2 & one spot in zone 3.

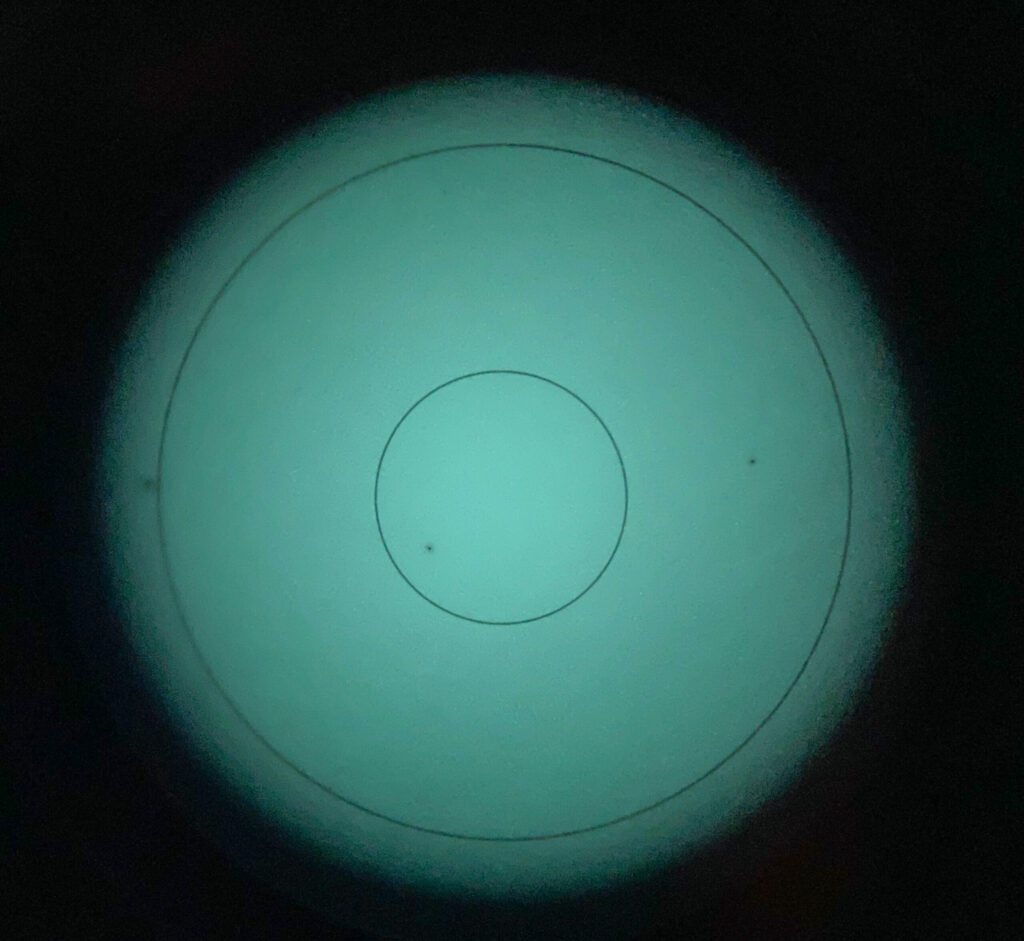

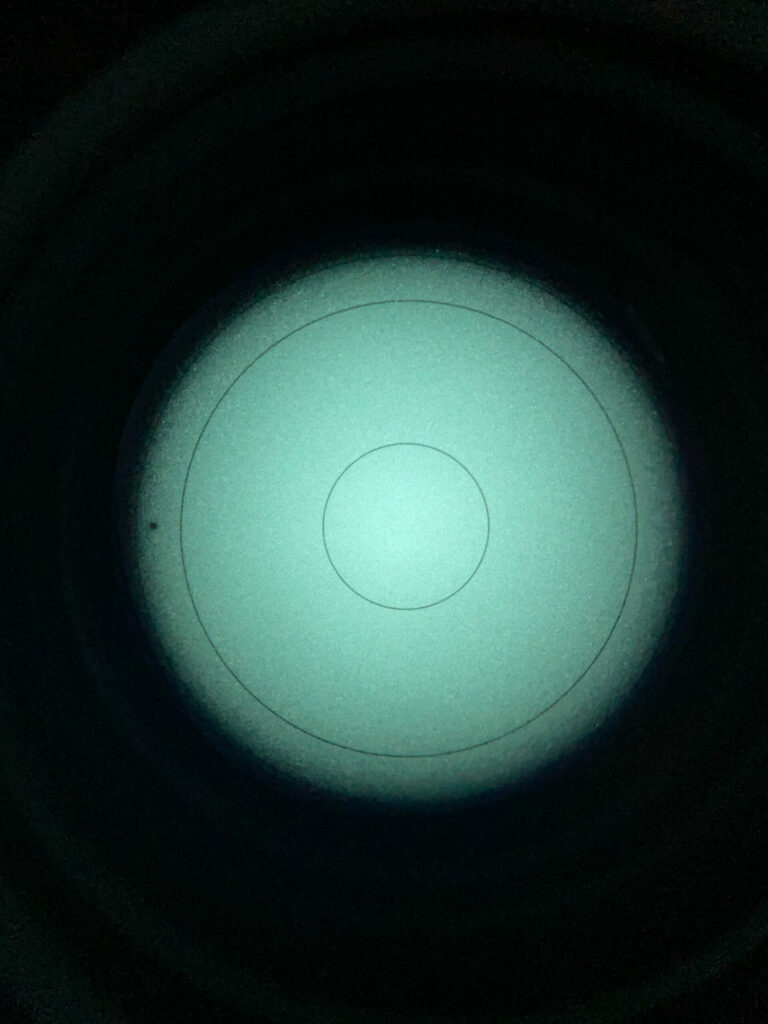

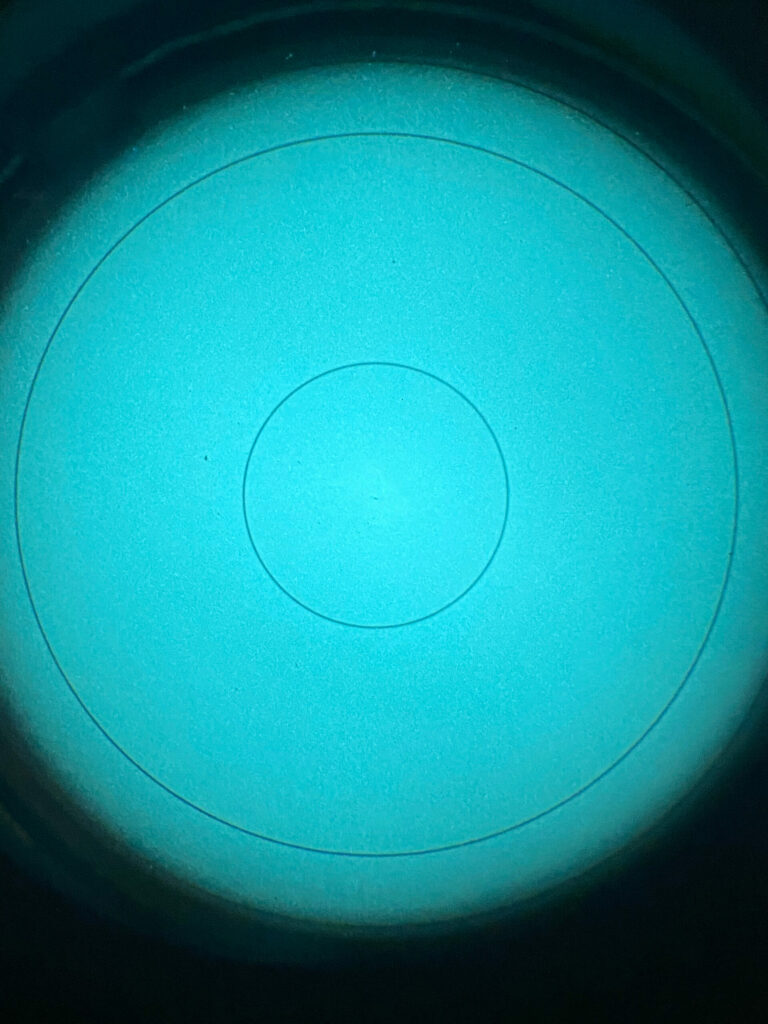

The strictest spot spec available is an aviation spot spec. Aviation spot specs were created at the request of the military to have cleaner tubes for their strict aviation needs. An aviation spot spec is max 3 spots per tube which are only allowable in zone 3. With no allowable spots greater than .003” in zone 1 or 2 the aviation spot spec is best for those who need the cleanest tubes possible. Because of the strict standard for an aviation tube we use these as a standard offering at Licentia Arms. We do this because like our customers, we demand the best.

Pictured above is an aviation grade spot spec example. This tube reads one spots larger than .003″ in zone 3.

Pictured above is an aviation grade spot spec example. This tube reads no spots larger than .003″ but slight peppering is visible in zone 1 & 2 (zoom in to see clearer)

**Disclaimer** This article is aimed at educating customers on the realities of spots in night vision. Please realize that these are just example pictures and are in no way indicative of the exact tube you may get under each spot spec. It is the buyers responsibility to understand what spot spec they are purchasing and the acceptable results that spot spec can produce.